The mighty Saturn V, the rocket that took humans to the moon, remains the tallest, heaviest, and most powerful rocket ever brought to operational status (as of 2018). It was used by NASA between 1967 and 1973. It was powered by five Rocketdyne F-1 engines. With a thrust of 1,746,000

Today, private companies like SpaceX, Blue Origin, and space agencies like NASA trying to build powerful rockets in order to reach Moon and Mars. But, we’ve already built a rocket that took us to the moon, why don’t we simply remake it (and the engines)? In the video below, Youtube user Curious Droid answers this question.

In a nutshell, we can’t (and we shouldn’t) remake Apollo Program’s mighty Rocketdyne F-1 engines because:

- The ultra-talented and experienced engineers who built the Rocketdyne F-1 engine were retired or long dead – and some of the crucial knowledge, skills, and experience were long gone with them.

- Many of those skills and techniques which was used to build F-1 engines are no longer in use. So we simply don’t have the people and skills that can make them in the same way anymore.

- With the help of powerful computers and new technologies, we can do a better job today (if we can find enough money to do that). With the examination of Rocketdyne F-1 engines from museums and storage, today’s engineers did discover enough to create a new F-1B engine should it ever be built. Using modern computing modeling and manufacturing techniques, the new engine could not only be more efficient, it would be just as powerful as the updated but unflown F-1A at 1.8 million pounds of thrust. More importantly, it would reduce the number of manufactured parts from around 5,600 to just 40! And while increasing its reliability and decreasing costs in the process.

I would recommend you subscribe to Curious Droid’s channel if you haven’t already.

Related: Saturn V Rocket (Documentary)

The Apollo 11 mission, the first crewed lunar mission, launched from the Kennedy Space Center, Florida via the Marshall Space Flight Center (MSFC) developed Saturn V launch vehicle on July 16, 1969, and safely returned to Earth on July 24, 1969. The Saturn V vehicle produced a holocaust of flames as it rose from its pad at Launch complex 39. The 363 foot (110.6 meters) tall, 6,400,000

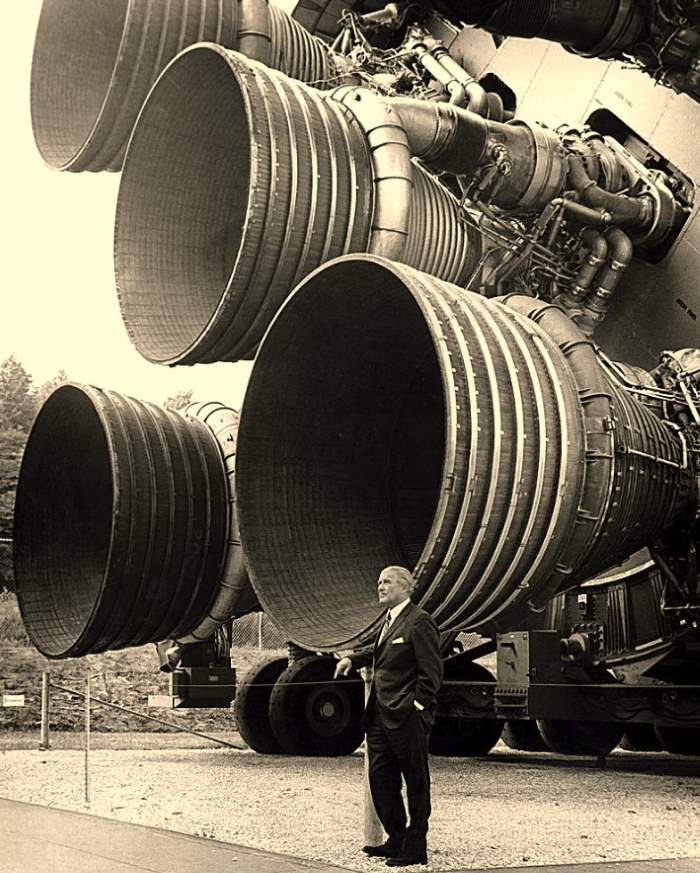

The mighty and huge Rocketdyne F-1 Engine

In the image above, German (and, later, American) aerospace engineer and space architect Dr. Wernher von Braun (March 23, 1912 – June 16, 1977) standing by five Rocketdyne F-1 Engines. A pioneer of America’s space program, Dr. von Braun stands by the five F-1 engines of the Saturn V Dynamic Test Vehicle on display at the U.S. Space & Rocket Center in Huntsville, Alabama.

Designed and developed by Rocketdyne under the direction of the Marshall Space Flight Center, a cluster of five F-1 engines was mounted on the Saturn V S-IC (first) stage. The engines measured 19-feet (5.8 meters) tall by 12.5-feet (3.8 meters) at the nozzle exit and burned 15 tons of liquid oxygen and kerosene each second to produce 7,500,000 pounds of thrust. The S-IC stage is the first stage, or booster, of a 364-foot long (110.9 meters) rocket that ultimately took astronauts to the Moon.

The Rocketdyne F-1 engine had roots outside NASA, born as an Air Force program developed by the aerospace firm Rocketdyne in 1955. NASA inherited it during a transfer of projects, conducted its own feasibility studies, and awarded Rocketdyne a follow-on contract to step up work on the gargantuan propulsion system not long after NASA’s formation, in 1960.

Each second, a single Rocketdyne F-1 engine burned 5,683 pounds (2,578 kg) of oxidizer and fuel: 3,945 lb (1,789 kg) of liquid oxygen and 1,738 lb (788 kg) of RP-1, generating 1,500,000 lbf (6.7 MN; 680 tf) of thrust. This equated to a flow rate of 671.4 US gal (2,542 l) per second; 413.5 US gal (1,565 l) of LOX and 257.9 US gal (976 l) of RP-1.

During their two-and-a-half minutes of operation, the five F-1s propelled the Saturn V vehicle to a height of 42 miles (222,000 ft; 68 km) and a speed of 6,164 mph (9,920 km/h). The combined flow rate of the five F-1s in the Saturn V was 3,357 US gal (12,710 l) per second, or 28,415 lb (12,890 kg). Each Rocketdyne F-1 engine had more thrust than the three Space Shuttle Main Engines combined.

A bullet-proof (actually bomb-proof!) design

The engine was designed for the human-rated safety concept, which requires that it be dynamically stable. If any of the engine’s systems are disturbed from any source, the system must automatically overcome the disturbance and return to stable operation.

To prove the F-1’s ability to stabilize, a method for creating artificial disturbance was introduced by detonating a bomb inside the combustion chamber near the injector face. Different injector designs were evaluated according to their ability to recover quickly from such disturbances. The result is an injector design in the present production configuration of the F-1 engine that has proved to be very quickly self-stabilizing in response to induced disturbances.

The powerful roar of Rocketdyne F-1 engines

Walter Cronkite (November 4, 1916 – July 17, 2009), covering the Apollo 4 launch for CBS News later admitted he was “overwhelmed” by the power of the Saturn V rocket and the emotion of the moment. His on-air description was delivered without his usual poise and reserve as he yelled above the launch noise into his microphone.

… our building’s shaking here. Our building’s shaking! Oh, it’s terrific, the building’s shaking! This big blast window is shaking! We’re holding it with our hands! Look at that rocket go into the clouds at 3000 feet! … you can see it… you can see it… oh the roar is terrific!

Walter Cronkite, Broadcast of Apollo 4 launch

Sources

- Rocketdyne F-1 on Wikipedia

- Saturn V on Wikipedia

- “The F-1 Engine Powered Apollo Into History, Blazes Path for Space Launch System Advanced Propulsion” on NASA.gov

- Background of the Rocketdyne F-1 Engine on NASA.gov

- How Many Elephants are Left in the World in 2025? - August 17, 2025

- Moon Landings: All-Time List [1966-2025] - February 2, 2025

- What Is Max-Q and Why Is It Important During Rocket Launches? - January 16, 2025

6 replies on “Why can’t we Remake the Rocketdyne F-1 Engine, which took humans to the Moon?”

It’s not the same exact engine obviously but there is this:

https://arstechnica.com/science/2013/04/how-nasa-brought-the-monstrous-f-1-moon-rocket-back-to-life/

Thanks for the comment and the link! Ars Technica is one of my favorite sites. You’re right, and Curious Droid also mentioned about that new engine in the video above (see after 3:45).

My father, Donald Eugene Davis, was able man on the crew that built the F-1 in Canoga Park,CA.

At 10 years old I was allowed in the factory with my dad. I got to touch one of them. They were huge.

My Father told me once that they built 65 engines that were never used and we’re stored in some wearhouse.

Thanks for the comment, Michael! It must be an amazing experience & memory. It’s also a pleasure to hear that your father was a part of the history of space exploration.

Late 1950 & early 1960 working with Packard Bell etc automatically checking out the Saturn C5 Booster & visiting Marshall Space Flight Center, I seemed to be the only Australian deeply involved in developing satellite instrumentation including my invention of a fist-size mass spectrometer etc. If I had your email address, i could send y’all a detailed report of my space contributions + photos. Right now the Brisbane Museum has been converted to a TOTAL space scene well worth the visit for a month more or so.

This is a update on this topic in light of Russia having stopped selling engines to the USA in retaliation for sanctions placed upon it due to their invasion of Ukraine. In regard to the Saturn 5 engine, I read a few years back that a group used modern CAD/CAM to recreate that engine, integrating many parts into one. Rather than thousands of parts it consisted of only about 45 or so. Yes we could build more of those engines and do it more quickly.