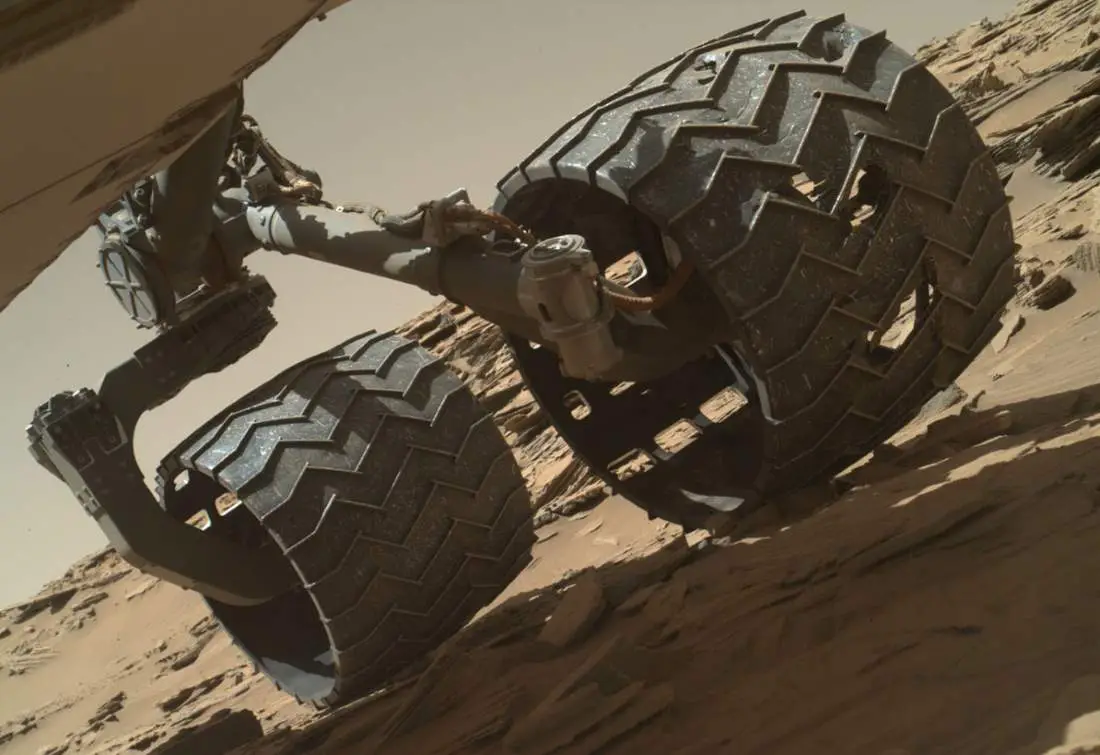

On August 6, 2012, at 05:17 UTC, NASA has successfully landed a Mini-Cooper-sized rover, Curiosity, on Aeolis Palus in Gale Crater on Mars. The 900-kg rover (899 kg, to be exact, which is 1,982 lbs) is equipped with six 50 cm (20 in) diameter wheels in a rocker-bogie suspension (see notes 1). For the first time in the history of space exploration, the suspension system also served as landing gear for the vehicle, unlike its smaller predecessors.

Curiosity “soft-landed” (wheels down) on the surface of Mars. But, even it’s called “soft-landing”, the touchdown speed was 0.6739m/s vertical and 0.044m/s horizontal, which could damage the wheels. Plus, while the rover is moving, the wheels should withstand the substantial damage through the rough Martian surface. That’s why the wheels of the Curiosity rover have been one of the biggest technical difficulties encountered on the mission (see notes 2).

“Reinventing” the wheel

Tire and wheel development for space exploration has been a focus of research at NASA Glenn (see notes 3) for decades. Evolving since the days of Apollo, NASA engineers started examining tire designs back in the 1960s for use on the surface of the Moon.

For early space exploration, NASA and other international researchers (the Soviet space program did not have central executive agencies, instead, its organizational architecture was multi-centered) introduced three-wheel designs:

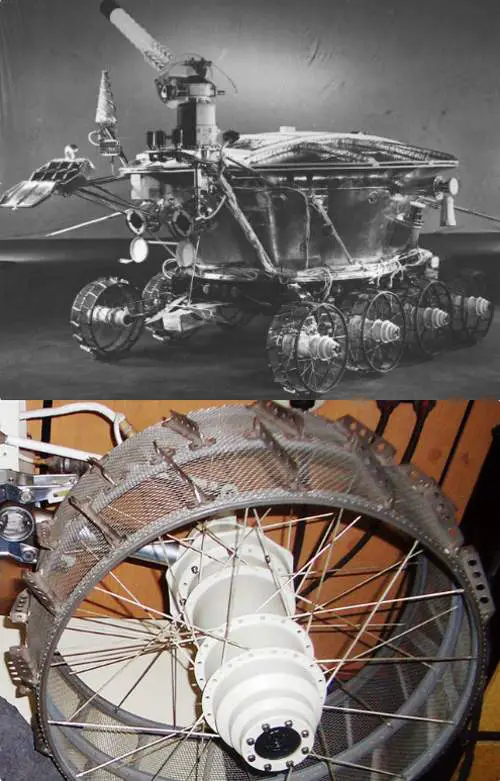

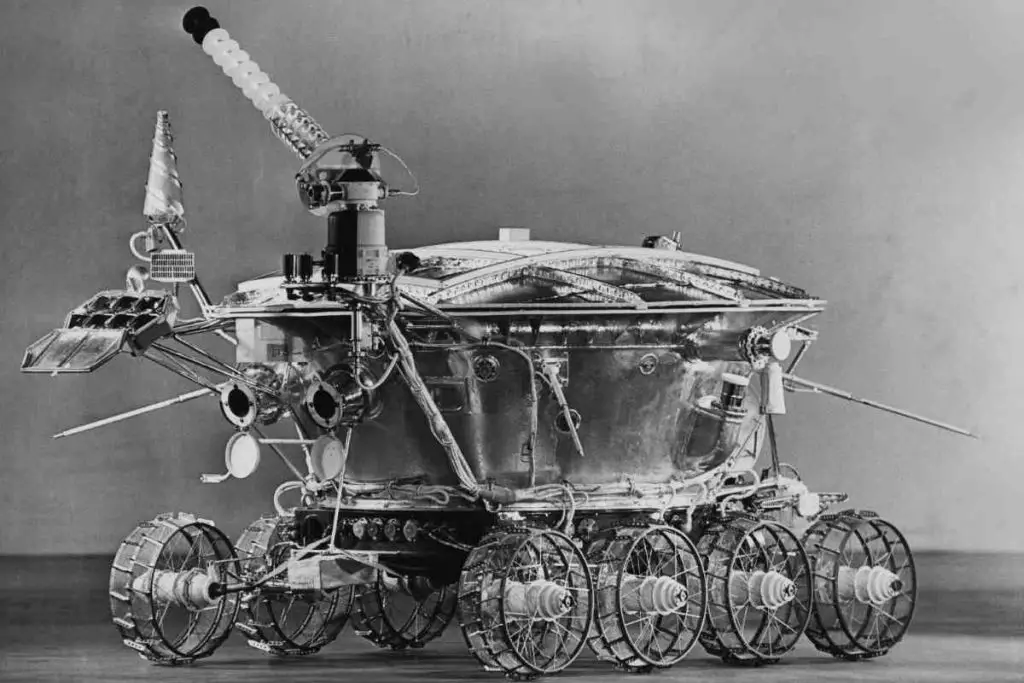

The Russian vehicle Lunokhod (Moonwalker in English), which was a series of Soviet robotic lunar rovers designed to land on the Moon between 1969 and 1977 used eight rigid rim wire mesh wheels with bicycle-type spokes and metal cleats for traction.

November 17, 1970, and September 14, 1971 (eleven lunar days) and traversed a total distance of 10.54 km. Lunokhod 1 used eight rigid rim wire mesh wheels with bicycle-type spokes and metal cleats for traction. Each of the eight wheels were independently powered. Image courtesy: Serguei Matrossov

Related: 50th anniversary of Lunokhod 1

The Modularized Equipment Transporter (MET) Rover was a two-wheeled cart featuring rubber tires that were inflated with nitrogen. They were designed to make it easier to pull the cart through the soft and forgiving lunar soil. The tires were manufactured by the American multinational tire manufacturing company Goodyear.

The last NASA vehicle to visit the Moon was the Lunar Roving Vehicle (popularly known as “Moon buggy”). It was used on the Moon in the last three missions of the American Apollo program (15, 16, and 17) during 1971 and 1972.

From the Moon to Mars

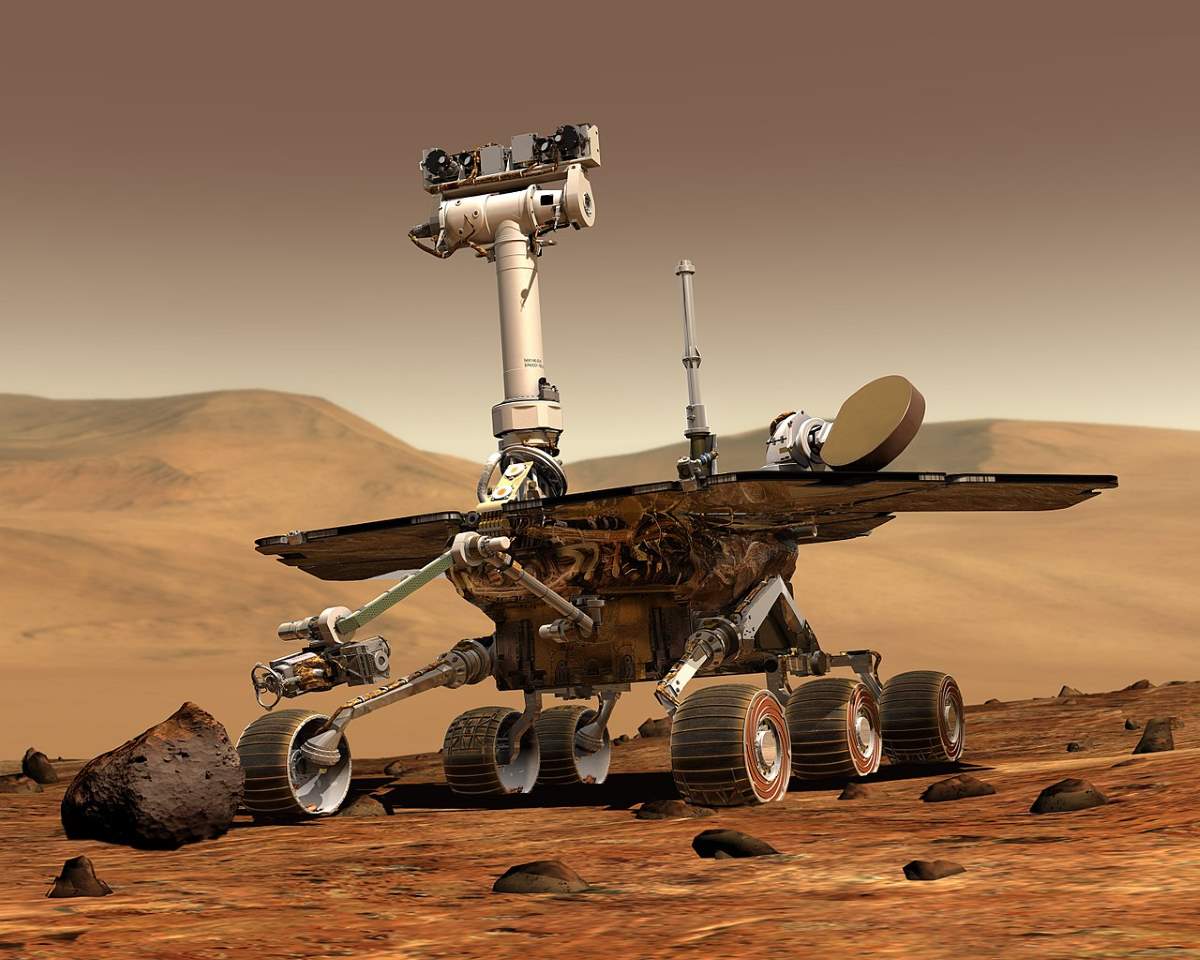

Before Curiosity, all Mars rovers (Sojourner, landed in 1997; Spirit, landed in 2004 and Opportunity, also landed in 2004) used solid aluminum wheels. But the Curiosity rover is much heavier. Even though it has a top speed of just 0.15 km/h (0.093 mph), this snail’s pace still had enough force to tear holes into its aluminum wheels.

The wheels had to be stiff enough for the weight of the rover (899 kg/1,982 lbs), need to be as light as possible to reduce launch cost, and must be able to maintain traction and navigate the unpredictable and rough Martian terrain. This wasn’t an easy task.

Unfortunately, NASA underestimated the roughness of the Mars terrain. 0.75 millimeter-thick wheels of Curiosity (around the same thickness as a credit card) began getting damaged pretty quickly. In 2013, a little over a year after the Mars Curiosity Rover landed on Mars, engineers began to notice significant wheel damage due to the unexpectedly harsh terrain, causing concern about the ability of the rover to drive far enough to complete its intended mission.

The Curiosity rover cost 2.5 billion dollars to develop. Extending the life of the mission was very important for NASA. Since there are There are no mechanics on Mars, the next best thing for the rover was careful driving.

To able to do this, a new algorithm was developed at JPL (Jet Propulsion Laboratory) by Jeff Biesiadecki and Olivier Toupet. The software, referred to as traction control, was adjusting the speed of Curiosity’s wheels depending on the rocks it’s climbing. After 18 months of testing at NASA’s Jet Propulsion Laboratory in Pasadena, California, the software was uploaded to the rover on Mars in March.

Future designs

Here on Earth, the air-filled rubber tires can withstand similarly rough terrains. So, why not use them on Mars?

This is impossible because of the climate of Mars. The r

Another problem is radiation. Mars has no magnetosphere (it has collapsed around 3.7 billion years ago) and its atmosphere is very thin, equivalent to about 1% of Earth’s at sea level. So, there’s no protection from solar winds on the surface of Mars. Rubber would also degrade from the UV radiation it would be exposed to.

Last but not least, rubber wheels are heavy. This would dramatically increase the launch cost.

Related: Terraforming Mars – why it’s so hard

Another option could be flexible wire mesh wheels with stiff inner frames, like those used on the Lunar Rover. This option was studied for applications on Mars, but the Lunar Rover had a mass of just 450 kg (992 lbs) compared to the 900 kilograms (1,884 lbs) of the Curiosity rover. Combine this with higher gravity on Mars (see notes 4), and it made these wheels unsuitable for the Martian terrain. The wheels simply not be able to hold the weight of the vehicle without deforming permanently.

Spring tires

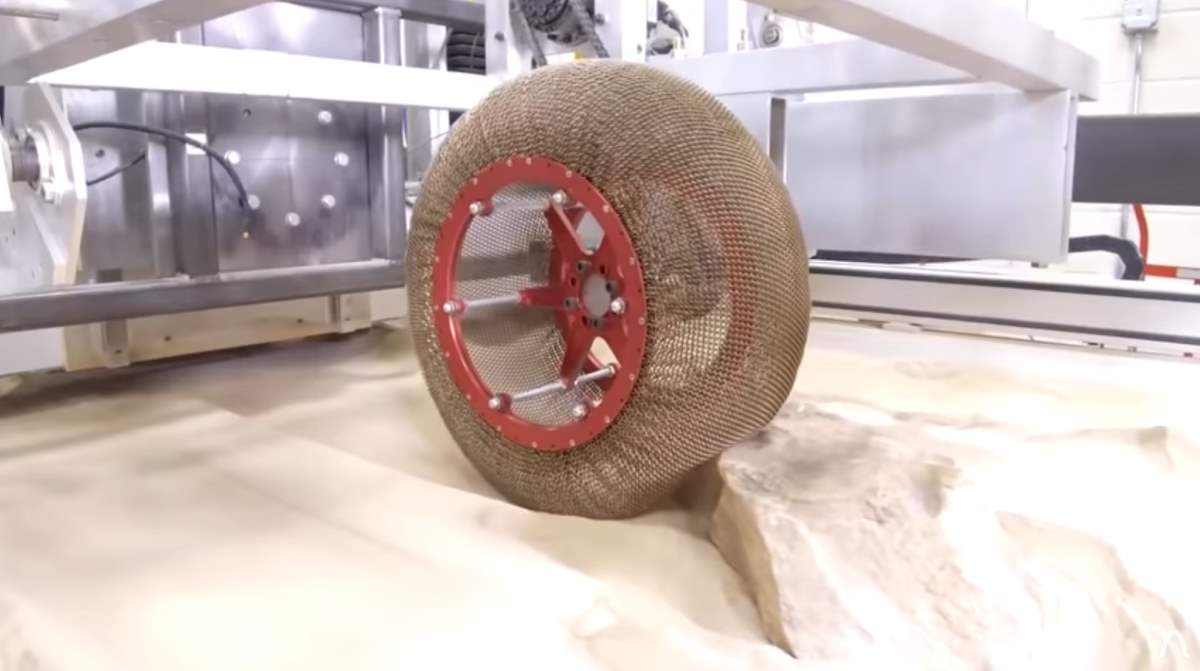

During the mid-2000s, NASA Glenn engineer Vivake Asnani worked with industry partner Goodyear to develop the Spring Tire, an airless compliant tire that consists of several hundred coiled steel wires woven into a flexible mesh, giving the tires the ability to support high loads while also conforming to the terrain. The Spring Tire has been proven to generate very good traction and durability in soft sand and on rocks. This innovation led to an R&D 100 Award for Top Inventions of the Year.

Spring tires are light, they are capable of bending, and conform to the terrain without permanently deforming. They are also capable of holding a heavy vehicle.

Engineers use a new material called Nickel titanium, also known as Nitinol (part of shape memory alloy). Nitinol alloys exhibit two closely related and unique properties: shape memory effect (SME) and superelasticity (SE; also called pseudoelasticity, PE).

Shape memory is the ability of nitinol to undergo deformation at one temperature, then recover its original, undeformed shape upon heating above its “transformation temperature”. Superelasticity occurs at a narrow temperature range just above its transformation temperature; in this case, no heating is necessary to cause the undeformed shape to recover, and the material exhibits enormous elasticity, some 10-30 times that of ordinary metal.

These incredible properties of Nitinol are not just good for applications in space, but right here on Earth.

After building the shape memory alloy tire, Glenn engineers sent it to JPL’s Mars Life Test Facility. It performed impressively on the punishing track (see the video below).

There are three major benefits to developing high performing compliant tires that are capable of performing in a Martian or Lunar environment:

- They would allow rovers to explore greater regions of the surface than currently possible.

- Because they conform to the terrain and do not sink as much as rigid wheels, they can carry heavier payloads for the same given mass and volume.

- Because the compliant tires can absorb energy from impacts at moderate to high speeds, they can be used on crewed exploration vehicles which are expected to move at speeds significantly higher than the current Mars rovers.

Notes

- The term “bogie” comes from old railroad systems. A bogie is a train undercarriage with wheels that can swivel to curve along a track. The term “rocker” comes from the design of the differential, which keeps the rover body balanced, enabling it to “rock” up or down depending on the various positions of the multiple wheels.

- U.S. bicycle manufacturer Litespeed has been a contractor and consultant to NASA for projects that require titanium-intensive sub-assemblies including the landing gear on the Curiosity.

- NASA Glenn Research Center is named after Colonel John Herschel Glenn Jr. (July 18, 1921 – December 8, 2016), a United States Marine Corps aviator, engineer, astronaut, businessman, and politician. He was the first American to orbit the Earth, circling it three times in 1962.

- Mars has a gravity of 3.711 m/s². Moon’s gravity is just 1.62 m/s², almost one-sixth of Earth’s gravity, which is 9.807 m/s²

Sources

- “Wheels and Legs” on NASA’s Curiosity Rover website

- Curiosity Rover on Wikipedia

- An Algorithm Helps Protect Mars Curiosity’s Wheels on NASA Jet Propulsion Laboratory website

- Litespeed on Wikipedia

- “Reinventing the wheel” on NASA website

- “The Aerospace Applications Of Nickel-titanium As a Superelastic Material” on Pitt.edu

- Nickel-titanium on Wikipedia

- Budget of NASA, Year by Year [1980-1989] - June 10, 2024

- Budget of NASA, Year by Year [1970-1979] - June 10, 2024

- Budget of NASA, Year by Year [1958-2024] - June 10, 2024